Products

Gas series

Gas series

Gas series

Gas series

Oil series

Oil series

Oil series

Oil series

Oil series

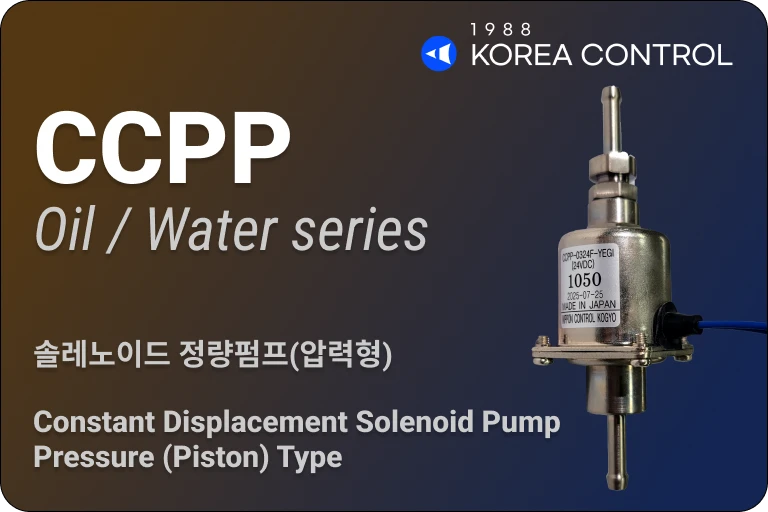

Oil/Water series

Oil/Water series

Oil series

Gas series

Gas series

Gas series

Gas series

2023

2023

2023

2023

2023

2023

Oil series

What is a Solenoid Valve?

A Solenoid Valve is a precision control device that uses electromagnetic force and spring action to automatically open and close the flow of fluids such as gas, water, oil, and steam. With fast response, high safety, and durability, solenoid valves are widely applied in industrial fluid control systems.

Gas Solenoid Valve

- Controls fuel gases such as LNG and LPG

- Applied in gas boilers, burners, and gas supply systems

- Ensures tight sealing and maximum safety

Liquid Solenoid Valve

- Controls liquids such as water and oil

- Used in hot & cold water systems, industrial plants, and sanitary equipment

- Excellent corrosion resistance and long durability

Air & Steam Solenoid Valve

- Controls air, compressed gas, and steam

- Applied in HVAC systems, automation equipment, and industrial facilities

- Stable performance in high-temperature and high-pressure conditions

Custom Solutions

Beyond standard gases, liquids, and steam, we provide custom solenoid valves designed to handle special conditions such as high temperature, high pressure, and corrosive environments.

We guarantee consistent quality throughout the entire process:

design → development → manufacturing → delivery.

What is a Solenoid Pump?

A Solenoid Pump (Electromagnetic Pump) uses electromagnetic force and spring action to create reciprocating motion, which allows the precise pumping and transfer of fluids such as water, oil, and chemicals. It features compact size, high efficiency, and easy maintenance, making it widely used in various industries.

Oil Solenoid Pump

Used in oil-fired water heaters and burners

Provides accurate fuel delivery and stable flow control

Supports fuel efficiency and reliable performance

Water & Chemical Solenoid Pump

Ideal for industrial systems requiring precise flow control

Applied in medical, sanitary, and laboratory equipment

Ensures safety with anti-corrosion and hygienic design

Custom Fluid Solutions

Beyond standard fluids like water, oil, and chemicals,

we offer custom solenoid pumps designed for special fluids through design → development → manufacturing → delivery,

ensuring consistent quality and tailored performance.

Applications of Our Products

Boilers & Water Heaters: Gas boilers, electric boilers, industrial water heaters

Burners & Combustion Equipment: Oil burners, gas burners, industrial heaters, kerosene stoves

Kitchen & Sanitary Equipment: Water purifiers, dishwashers, urinals, coffee dispensers, industrial cleaning machines

Medical & Laboratory Devices: Chemical dosing equipment, medical washers, sanitary systems, precision laboratory instruments

Industrial Automation Systems: Hot & cold water control, fluid handling equipment, plant facilities

Automotive & Mobility Components: Vehicle parts, fuel supply systems, fuel cells

💡 Custom Solutions

Beyond standard gases, liquids, and steam, we offer custom solenoid pumps and valves designed for high temperature, high pressure, and corrosive fluids,

ensuring consistent quality through the entire process: design → development → manufacturing → delivery.

Questions & Answers

What services do you provide?

We offer custom development services for solenoid pumps and valves tailored to customer requirements.

Designs are optimized based on fluid type, flow rate, pressure, and power conditions, and we support the entire process from prototype production to mass manufacturing.

How is a new development project carried out?

A project proceeds in the following steps:

Receiving customer requirements and operating environment

Specification review and proposal submission

Prototype design and production

Testing and modifications

Transition to mass production

How long does the development take?

In general, it takes about 4 to 6 weeks from finalizing specifications to producing a prototype,

and approximately 8 to 12 weeks to transition into mass production.

For more complex specifications, the schedule may be extended.

What are the development costs?

The basic development cost starts from KRW 3–5 million.

Additional quotations are provided depending on factors such as prototype quantity, performance testing, certification requirements, and mold production.

※ The initial consultation is free of charge.

What systems are compatible?

Our products support DC 12V / 24V control systems and can be integrated with various platforms such as PLC, Arduino, Raspberry Pi, and IoT controllers.

If required, connectors and communication methods can also be customized to meet customer needs.

Technology that controls the flow, Precision that drives the future.

Korea Control Co., Ltd.

designs the heart of industry.